Qedela umugqa wokukhiqiza womanyolo oyinhlanganisela

Umugqa ophelele wokukhiqiza womanyolo womquba wemfuyo ubandakanya izinqubo ezimbalwa eziguqula imfucuza yezilwane ibe umanyolo wezinga eliphezulu wemvelo.Izinqubo ezithile ezihilelekile zingahluka kuye ngohlobo lwemfucuza yezilwane ezisetshenziswayo, kodwa ezinye zezinqubo ezivamile zihlanganisa:

1.Ukuphatha impahla eluhlaza: Isinyathelo sokuqala sokukhiqiza umanyolo wemfuyo ukuphatha izinto ezingavuthiwe ezizosetshenziswa ukwenza umanyolo.Lokhu kuhlanganisa ukuqoqa nokuhlunga ubulongwe bezilwane emfuyweni efana nezinkomo, izingulube, nezinkukhu.

2.Ukuvutshelwa: Imfucumfucu yezilwane ibe isicutshungulwa ngenqubo yokuvutshelwa, okubandakanya ukudala indawo evumela ukuwohloka kwezinto eziphilayo yizinambuzane.Le nqubo iguqula imfucuza yezilwane ibe umquba onomsoco.

3.Ukuchotshozwa nokuhluza: Umquba ube usugaywa futhi uhlolwe ukuze kuqinisekiswe ukufana kwengxube futhi kukhishwe noma yiziphi izinto ezingadingeki.

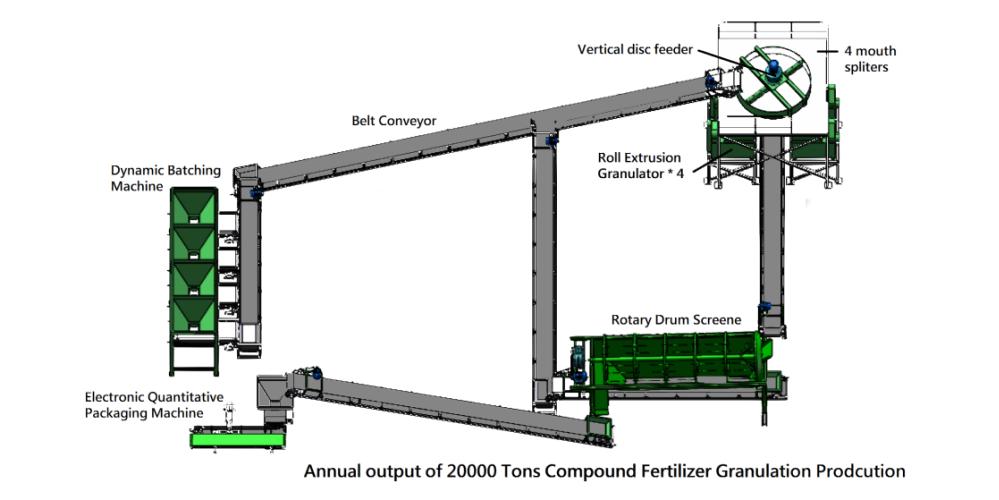

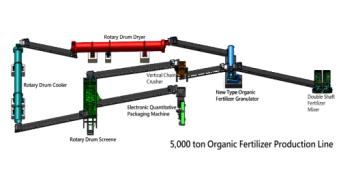

4.I-Granulation: Umquba ube usukwakhiwa ube yizinhlayiyana kusetshenziswa umshini wokuhlanganisa.I-granulation ibalulekile ukuqinisekisa ukuthi umanyolo kulula ukuphatha nokusebenzisa, nokuthi ukhulula imisoco yawo kancane ngokuhamba kwesikhathi.

5.Ukomisa: Ama-granules asanda kwakhiwa abe eseyomiswa ukuze asuse noma imuphi umswakama okungenzeka ukuthi ungeniswe phakathi nenqubo yokuhlanganisa.Lokhu kubalulekile ukuze kuqinisekiswe ukuthi ama-granules awaqoqeki ndawonye noma awonakalise ngesikhathi sokugcinwa.

6.Ukupholisa: Ama-granules omisiwe abe esepholiswa ukuze kuqinisekiswe ukuthi asezingeni lokushisa elizinzile ngaphambi kokuba ahlanganiswe futhi athunyelwe.

7.Ukupakisha: Isinyathelo sokugcina ekukhiqizweni kukamanyolo wemfuyo ukupakisha ama-granules ezikhwameni noma kwezinye iziqukathi, ezilungele ukusatshalaliswa nokudayiswa.

Ukucatshangelwa okubalulekile ekukhiqizweni komanyolo wemfuyo yithuba lamagciwane kanye nokungcola emfuleni wezilwane.Ukuqinisekisa ukuthi umkhiqizo wokugcina uphephile ukusetshenziswa, kubalulekile ukusebenzisa izinyathelo ezifanele zokukhucululwa kwendle kanye nokulawula ikhwalithi kuyo yonke inqubo yokukhiqiza.

Ngokuguqula imfucumfucu yezilwane ibe umkhiqizo womanyolo obalulekile, umugqa ophelele wokukhiqiza womanyolo womquba wemfuyo ungasiza ekunciphiseni imfucumfucu futhi ukhuthaze izinqubo zezolimo ezisimeme kuyilapho uhlinzeka ngomanyolo wemvelo wezinga eliphezulu nosebenzayo wezitshalo.