Inqubo yomugqa wokukhiqiza we-disk granulation ephelele futhi ehlukahlukene ingenye yezinzuzo eziyinhloko ze-Henan Zheng Heavy Industries.Inganikeza izixazululo eziphelele nezithembekile zomugqa wokukhiqiza ngokwezidingo zangempela zamakhasimende.

Sinolwazi ekuhleleni nasekusebenzeleni imigqa ehlukahlukene yokukhiqiza umanyolo.Asigxili kuphela kuso sonke isixhumanisi senqubo enqubweni yokukhiqiza, kodwa futhi njalo sibamba imininingwane yenqubo ngayinye kuwo wonke umugqa wokukhiqiza futhi sizuze ukuxhumanisa ngempumelelo.

Umugqa wokukhiqiza we-disk granulator usetshenziswa kakhulu ukukhiqiza umanyolo we-organic.Umanyolo wemvelo ungenziwa ngomquba wemfuyo nezinkukhu, udoti wezolimo kanye nemfucuza kamasipala.Le mfucumfucu yemvelo idinga ukuphinde icutshungulwe ngaphambi kokuthi iguqulwe ibe ngumanyolo wezohwebo wenani lezentengiselwano ukuze ithengiswe.Ukutshalwa kwezimali ekuguquleni udoti ube ingcebo kuwufanele ngempela.

Umugqa wokukhiqiza umanyolo we-Disc granulated organic ulungele:

- ►Ukukhiqiza ubulongwe benkomo umanyolo eziphilayo

- ►Ukwenziwa komanyolo wezingulube ophilayo

- ►Ukwenziwa komanyolo we-organic wenkukhu namadada

- ►Ukukhiqiza umanyolo wezimvu ngokwemvelo

- ►Ukukhiqizwa kukamanyolo we-organic of sludge yasemadolobheni

1. umquba wezilwane: umquba wenkukhu, umquba wezingulube, umquba wezimvu, umquba wenkomo, umquba wamahhashi, umquba onogwaja, njll.

2. imfucuza yezimboni: amagilebhisi, i-slag yeviniga, izinsalela ze-cassava, izinsalela zikashukela, imfucumfucu ye-biogas, izinsalela zoboya, njll.

3. Imfucuza yezolimo: utshani bezitshalo, ufulawa kabhontshisi wesoya, impushana yembewu kakotini, njll.

4. Imfucuza yasekhaya: udoti wasekhishini

5. udaka: udaka lwasemadolobheni, udaka lomfula, udaka lokuhlunga, njll.

Ulayini wokukhiqiza i-disk granulation usuthuthukisiwe, uyasebenza futhi uyasebenza, isakhiwo semishini sihlangene, i-automation iphakeme, futhi ukusebenza kulula, okulungele ukukhiqizwa ngobuningi komanyolo we-organic.

1. Izinto ezimelana nokubola nezingagugi zisetshenziswa kuzo zonke izinto zomugqa wokukhiqiza.Akukho kukhishwa kukadoti okuthathu, ukonga amandla nokuvikelwa kwemvelo.Isebenza kancane futhi kulula ukuyinakekela.

2. Amandla okukhiqiza angalungiswa ngokuvumelana nezidingo zamakhasimende.Ukuhlelwa kwawo wonke umugqa wokukhiqiza kuhlangene, kwesayensi futhi kunengqondo, futhi ubuchwepheshe buthuthukile.

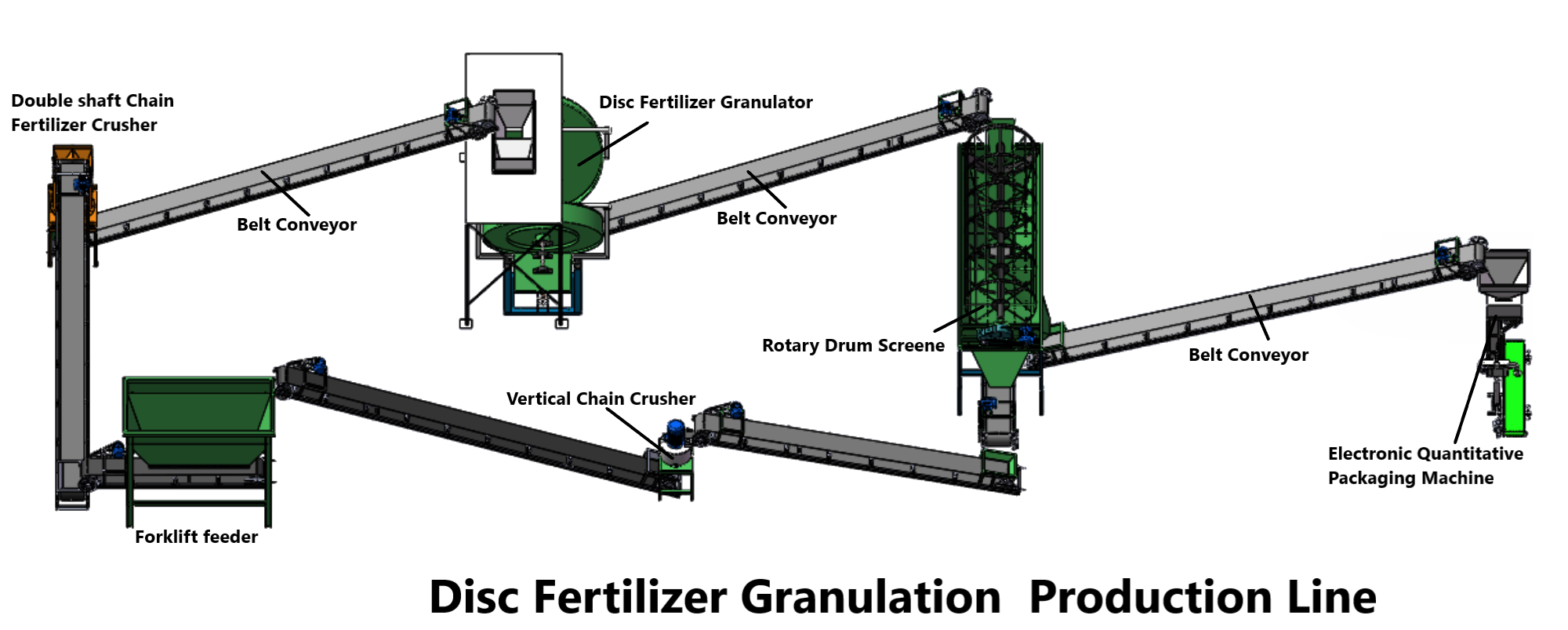

Imishini yokukhiqiza i-disc granulation ihlanganisa indawo yokugcina izithako → i-blender (i-sirring) → umshini wokugcwalisa i-disk granulation (i-granulator) → umshini wesisefo we-roller (uhlukanisa imikhiqizo esezingeni eliphansi emikhiqizweni eqediwe) → i-crusher yeketango eqondile (ephukayo) → umshini wokupakisha ozenzakalelayo (ukupakishwa) → isihambisi sebhande ( ukuxhuma kuzinqubo ezahlukahlukene).

Qaphela: lo mugqa wokukhiqiza owokubhekisela kuphela.

Ukugeleza kwenqubo yomugqa wokukhiqiza we-disk granulation ngokuvamile kungahlukaniswa kube:

1. Inqubo yezithako zezinto ezibonakalayo

Ukulinganisa okuqinile kwempahla eluhlaza kungaqinisekisa ukusebenza kahle kukamanyolo.Izinto ezisetshenziswayo zihlanganisa indle yezilwane, izithelo ezibolile, amakhasi, imifino eluhlaza, umanyolo oluhlaza, umanyolo wasolwandle, umanyolo wasemapulazini, imfucuza emithathu, amagciwane kanye nezinye izinto ezingavuthiwe.

2. Inqubo yokuxuba impahla eluhlaza

Zonke izinto zokusetshenziswa zixutshwe futhi zixutshwe ngokulinganayo ku-blender.

3. Inqubo ephukile

I-crusher yeketango eqondile igxoba izingcezu ezinkulu zezinto zibe izingcezu ezincane ezingahlangabezana nezidingo ze-granulation.Khona-ke i-conveyor yebhande ithumela izinto emshinini we-disk granulation.

4. Inqubo ye-granulation

I-disk angle yomshini we-disk granulation ithatha isakhiwo se-arc, futhi izinga lokwakheka kwebhola lingafinyelela ngaphezu kwama-93%.Ngemuva kokuthi izinto zingene epuleti le-granulation, ngokujikeleza okuqhubekayo kwediski ye-granulation kanye nedivayisi yesifutho, impahla ihlanganiswa ngokulinganayo ukuze ikhiqize izinhlayiya ezinomumo ofanayo kanye nesimo esihle.

5. Inqubo yokuhlola

Izinto ezipholile zithuthelwa emshinini wokusefa we-roller ukuze zihlolwe.Imikhiqizo efanelekayo ingangena endaweni yokugcina impahla eqediwe ngokusebenzisa i-conveyor yebhande, futhi ingahlanganiswa ngokuqondile.Izinhlayiya ezingafanelekile zizobuyela ku-regrainate.

6. Inqubo yokupakisha

Ukupakisha kuyinqubo yokugcina yomugqa wokukhiqiza umanyolo we-organic.Umkhiqizo oqediwe upakishwa ngomshini wokupakisha owumthamo ozenzakalelayo.Izinga eliphezulu le-automation kanye nokusebenza kahle okuphezulu akuzuzi nje kuphela ukukala okunembile, kodwa futhi nokuqedela kahle inqubo yokugcina.Abasebenzisi bangalawula isivinini sokuphakelayo futhi basethe imingcele yesivinini ngokwezidingo zangempela.