I-granulator eyomile

I-granulator eyomile, eyaziwa nangokuthi umshini wokugaya owomile, iyisisetshenziswa esikhethekile esiklanyelwe ukuhlanganisa izinto ezomile ngaphandle kwesidingo sezibophelelo eziwuketshezi noma izincibilikisi.Le nqubo ihlanganisa ukuhlanganisa kanye nokubumba izimpushana ezomile noma izinhlayiya zibe yizinhlayiyana, okulula ukuziphatha, ukuzigcina, kanye nokuthutha.Kulesi sihloko, sizohlola izinzuzo, isimiso sokusebenza, kanye nokusetshenziswa kwama-granulator omile ezimbonini ezihlukahlukene.

Izinzuzo ze-Dry Granulation:

Awekho Ama-Liquid Binders noma Ama-Solvents: I-granulation eyomile iqeda isidingo sokuhlanganisa uketshezi noma izincibilikisi ezivame ukusetshenziswa ezinqubweni ze-granulation ezimanzi.Lokhu kunciphisa inkimbinkimbi yenqubo ye-granulation, kwenza ukuphatha nokuhlanza kube lula, futhi kuqede ingozi yokungcoliswa okuphambene noma ukukhathazeka kwemvelo okuhlotshaniswa nezibophezelo ezisekelwe kuketshezi.

Ukuzinza Okuthuthukisiwe: Ama-granules omile athuthukise ukuzinza uma kuqhathaniswa nezimpushana noma izinhlayiya ezixekethile.Imvelo ehlangene yama-granules inciphisa ukuhlukaniswa, ivimbela ukumuncwa komswakama, futhi ithuthukise izici zokugeleza.Lokhu kuzinza kuqinisekisa ikhwalithi yomkhiqizo engaguquki futhi kunciphisa ingozi yokuwohloka ngesikhathi sokugcinwa noma ukuthuthwa.

Ukonga Izindleko: I-granulation eyomile inikeza izinzuzo zezindleko ngokususa isidingo sezibophezelo eziwuketshezi, izinqubo zokomisa, nezisetshenziswa ezihambisanayo.Yehlisa ukusetshenziswa kwamandla, isikhathi sokukhiqiza, kanye nezidingo zokunakekela, okuholela ekongeni kwezindleko zabakhiqizi.

Izakhiwo Ze-Granule Ezenzeka Ngokwezifiso: Imbudumbudu eyomile ivumela ukulawula okunembile phezu kwezakhiwo ze-granule, njengosayizi, umumo, ukuminyana, kanye ne-porosity.Lokhu kwenza abakhiqizi bakwazi ukuhlanganisa ama-granules ukuze ahambisane nezidingo ezithile zohlelo lokusebenza, ukuqinisekisa ukusebenza kahle nezici zomkhiqizo ezifiselekayo.

Umgomo Wokusebenza Wama-Granulator Ewomile:

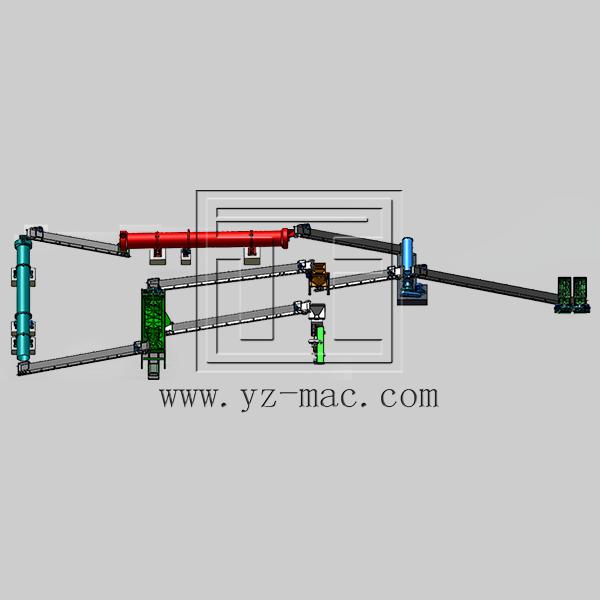

Ama-granulator omile ngokuvamile asebenzisa izinqubo ezimbili eziyinhloko: ukuhlanganisa nokugaya.

Ukuminyana: Esigabeni sokuminyana, izimpushana ezomile noma izinhlayiya zifakwa egumbini le-granulation, lapho ipheya yamaroli aphendukayo noma umshini wokunyathelisa usebenzisa ingcindezi ukuze kuhlanganiswe okokusebenza.Izinto ezihlanganisiwe zenza i-plastic deformation, yenze iribhoni noma ishidi.

Ukugaya: Iribhoni elihlanganisiwe noma ishidi libe selidluliswa ohlelweni lokugaya, oluhlanganisa iqoqo lemimese noma izindwani ezihlephula impahla ibe yizinhlamvana zosayizi oyifunayo.Ama-granules agayiwe ayaqoqwa futhi angabhekana nezinyathelo ezengeziwe zokucubungula, ezifana nokusefa noma ukumbozwa, uma kunesidingo.

Izicelo zama-Dry Granulators:

Imboni Yemithi: I-granulation eyomile isetshenziswa kakhulu ekwenzeni imithi ukuze kukhiqizwe amaphilisi, amaphilisi, namanye amafomu omthamo oqinile.Ivumela ukucindezelwa okuqondile kwezimpushana zezidakamizwa zibe yizinhlayiyana, kuthuthukiswe ukugeleza, ukufana, kanye nokukwazi ukubhebhetheka.Ama-granulator omile afaneleka kokubili ukukhiqizwa kwemithi emincane kanye nenkulu.

Imboni Yamakhemikhali: I-granulation eyomile isetshenziswa embonini yamakhemikhali ukuze kukhiqizwe umanyolo we-granular, ama-catalysts, ama-pigments, neminye imikhiqizo yamakhemikhali.Inqubo inika amandla ukulawula okunembile phezu kwezakhiwo zegranule, njengosayizi, ukuminyana, kanye ne-porosity, iqinisekisa ikhwalithi yomkhiqizo engaguquki nezici zokuphatha ezithuthukisiwe.

Imboni Yokudla Nokudla Okunomsoco: I-granulation eyomile isetshenziswa ezimbonini zokudla nezomsoco ukuze kukhiqizwe izithako ze-granular, izithasiselo zokudla, nezithasiselo zokudla.Ivumela ukwakhiwa kwezingxube zangokwezifiso, amasistimu okukhishwa alawulwayo, nokugeleza okuthuthukisiwe kokucubungula okuphumelelayo kanye nokwenza lula umthengi.

I-Powder Metallurgy: Imbudumbudu eyomile idlala indima ebalulekile ku-powder metallurgy, lapho izimpushana zensimbi zihlanganiswa futhi zenziwe yi-granulated ukuze zenze izitokwe zokudla zezinqubo ezilandelayo ezifana nokuhlanganisa, ukucwiliswa, nokubunjwa.Imbudumbudu eyomile ithuthukisa izici zokugeleza, ukuminyana, kanye nokufana kwezimpushana zensimbi, kube lula ukuphatha kwazo kanye nemisebenzi yokukhiqiza elandelayo.

Isiphetho:

Ama-granulator omisiwe anikeza i-granulation ephumelelayo futhi engabizi yezinto ezomile ngaphandle kwesidingo sezibophelelo eziwuketshezi noma izincibilikisi.Ngezinzuzo ezifana nokuzinza okuthuthukisiwe, ukonga izindleko, kanye nezakhiwo ze-granule ezenziwe ngendlela oyifisayo, imbudumbudu eyomile ithole izinhlelo zokusebenza ezimbonini ezahlukahlukene, ezifaka ezamakhemisi, amakhemikhali, ukudla, okomsoco, kanye ne-powder metallurgy.Ngokusebenzisa izimbudumbudu ezomile, abakhiqizi bangafinyelela ikhwalithi yomkhiqizo engaguquki, bathuthukise izici zokuphatha, futhi bathuthukise izinqubo zabo zokukhiqiza.