Impahla yokufaka umquba kamanyolo wemfuyo

Impahla yokuhlanganisa umquba kamanyolo wemfuyo iklanyelwe ukuguqula umquba ongahluziwe ube yimikhiqizo kamanyolo we-granular, okwenza kube lula ukuwugcina, ukuthuthwa, nokusetshenziswa.I-granulation iphinde ithuthukise okuqukethwe kwezakhi kanye nekhwalithi yomanyolo, okwenza ukuthi iphumelele kakhulu ekukhuleni kwezitshalo kanye nesivuno sezitshalo.

Izinto ezisetshenziswa ekuhlanganiseni umanyolo womquba wemfuyo zihlanganisa:

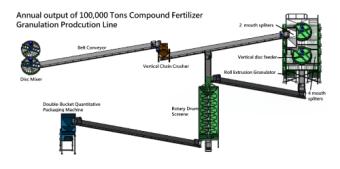

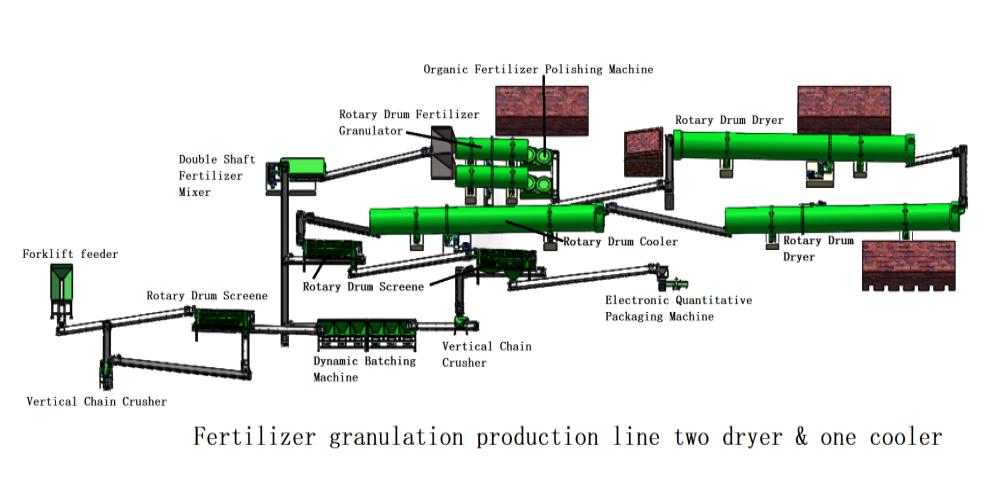

1.Ama-Granulator: Le mishini isetshenziselwa ukuhlanganisa nokubumba umquba ongahluziwe ube yizinhlamvana ezinosayizi nokuma okufanayo.Ama-Granulator angaba uhlobo olujikelezayo noma lwediski, futhi eze ngebanga losayizi nemiklamo.

I-2.Dryers: Ngemva kwe-granulation, umanyolo udinga ukoma ukuze ususe umswakama owedlulele futhi ukwandise impilo yawo yeshalofu.Izinto zokomisa zingaba uhlobo lombhede ojikelezayo noma omanzi, futhi ziza ngosayizi nemiklamo eyahlukene.

3.Ama-coolers: Ngemva kokoma, umanyolo udinga ukupholiswa ukuze uvimbele ukushisa ngokweqile futhi unciphise ingozi yokumunca umswakama.Izinto zokupholisa zingaba uhlobo lombhede olujikelezayo noma olunamanzi, futhi luze ngosayizi nemiklamo eyahlukene.

I-4.Imishini yokugqoka: Ukugqoka umanyolo ngesendlalelo sokuzivikela kungasiza ekunciphiseni ukumuncwa komswakama, ukuvimbela i-caking, nokuthuthukisa izinga lokukhululwa kwezakhi.Izinto zokumboza zingaba uhlobo lwesigubhu noma uhlobo lombhede olunamanzi.

I-5.Imishini yokuhlola: Uma inqubo ye-granulation isiqediwe, umkhiqizo oqediwe udinga ukuhlolwa ukuze kukhishwe noma yiziphi izinhlayiya ezinkulu noma ezingaphansi kanye nezinto zangaphandle.

Uhlobo oluthile lwempahla yokuhlanganisa umanyolo kamanyolo wemfuyo olulungele umsebenzi othile luzoncika ezintweni ezifana nohlobo kanye nenani lomquba okufanele lucutshungulwe, umkhiqizo wokugcina ofunekayo, nendawo etholakalayo kanye nezinsiza.Ezinye izinto zokusebenza zingase zilungele imisebenzi emikhulu yemfuyo, kanti ezinye zingase zifaneleke kakhulu ekusebenzeni okuncane.