Iukwethulwa kweCompound Fertilizer Production Line

ICompound Fertilizer umanyolo oqukethe imisoco emibili noma emithathu yeN, P;K. Umanyolo oyinhlanganisela utholakala uyimpushana noma uyimbudumbudu.Ngokuvamile isetshenziswa njengokugqoka okuphezulu futhi ingasetshenziswa futhi njengomanyolo wesisekelo kanye nomquba wembewu.Umanyolo ohlanganisiwe uqukethe izingxenye eziphezulu ezisebenzayo, ngakho-ke uncibilika kalula emanzini, ubola ngokushesha, futhi udonswa kalula yisistimu yezimpande, ngakho ubizwa ngokuthi "umanyolo osebenza ngokushesha".Umsebenzi wawo ukuhlangabezana nesidingo esibanzi nokulinganisa imisoco ehlukene edingwa izitshalo ngaphansi kwezimo ezahlukene.

Lo mugqa wokukhiqiza umanyolo usetshenziselwa ikakhulukazi ukugaxa ama-granules omanyolo ahlanganisiwe usebenzisa izinto ze-NPK, GSSP, SSP, granulated potassium sulphate, sulfuric acid, ammonium nitrate, nezinye.Imishini kamanyolo ehlanganisiwe inezinzuzo zokusebenzisa izinga lokungasebenzi kahle, eliphansi, ukulungiswa okuncane kanye nenani eliphansi.

Wonke ulayini wokukhiqiza ufakwe izinto ezithuthukisiwe nezisebenza kahle, ezingafinyelela umphumela wonyaka wamathani angama-50,000 kamanyolo oyinhlanganisela.Ngokwezidingo zangempela zamandla okukhiqiza, sihlela futhi siklame imigqa yokukhiqiza kamanyolo ehlanganisiwe enamandla ahlukahlukene wonyaka angamathani ayi-10,000 ~ 300,000.Isethi yonke yemishini ihlangene, inengqondo, isayensi, ukusebenza okuzinzile, ukonga amandla, izindleko zokunakekela eziphansi, kulula ukuyisebenzisa, kuyisinqumo esingcono kakhulu sabakhiqizi bakamanyolo abahlanganisiwe.

Inqubo yokukhiqiza umanyolo oyinhlanganisela emaphakathi

Inqubo yokukhiqiza umanyolo oyinhlanganisela ingahlukaniswa ngokujwayelekile ibe: ukuhlanganisa impahla eluhlaza, ukuxutshwa, ukuchotshozwa, i-granulating, ukuhlolwa okuyisisekelo, ukomiswa kwe-granule nokupholisa, ukuhlolwa kwesibili, ukumbozwa kwegranule kanye nokupakishwa komthamo.

1. Ukuhlanganisa izinto ezingavuthiwe: ngokwesidingo semakethe kanye nemiphumela yokunqunywa kwenhlabathi yendawo, izinto ezingavuthiwe ezifana ne-urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, calcium heavy, calcium general) nepotassium chloride ( potassium sulphate) izokwabelwa ngesilinganiso esithile.Izengezo kanye nezakhi zokulandelela zikalwa ngesilinganiso sebhande futhi zilinganiswe nengxenye ethile.Ngokwesilinganiso sefomula, zonke izinto zokusetshenziswa zixutshwa ngokulinganayo yi-mixer.Le nqubo ibizwa ngokuthi i-premix.Iqinisekisa ukwakheka okunembile futhi inika amandla ukuhlanganisa okuphumelelayo nokuqhubekayo.

2. Ukuxuba: Xuba ngokugcwele izinto ezingavuthiwe ezilungisiwe bese uzigoqa ngokulinganayo, okubeka isisekelo somanyolo wegranular osebenza kahle futhi osezingeni eliphezulu.I-mixer evundlile noma i-disc mixer ingasetshenziselwa ngisho nokuxuba.

3. Ukuchotshozwa: Ukuchoboza i-caking ezintweni ezidingekayo ukuze kusetshenziswe i-granulation elandelayo.I-Chain crusher isetshenziswa kakhulu.

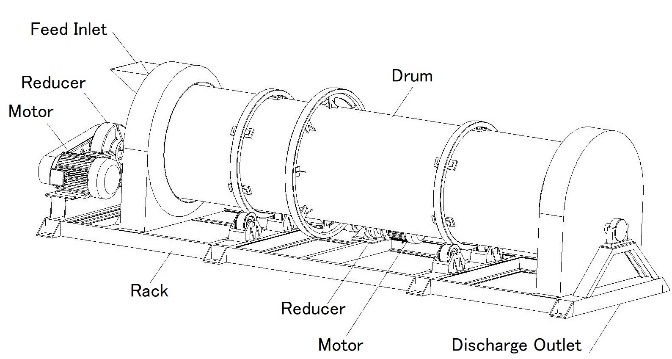

4. I-Granulating: Izinto ezinyakaziswe ngokulinganayo nezichotshoziwe zithuthelwa ku-granulator ngokusebenzisa i-conveyor yebhande ye-granulating, okuyingxenye eyinhloko yawo wonke umugqa wokukhiqiza.Ukukhethwa kwe-granulator kubaluleke kakhulu, sine-disc granulator, i-rotary drum granulator, i-roller extrusion granulator noma i-compound fertilizer granulator esingakhetha ngayo.

5. Ukuhlola okuyinhloko: Thatha ukuhlolwa kokuqala ukuze uthole ama-granules, futhi ubuyisele angafanelekile ekugayweni ukuze acutshungulwe kabusha.Ngokuvamile, kusetshenziswa umshini wokuhlola ojikelezayo.

6. Ukomisa: Ama-granules afanelekayo ngemva kokuhlolwa okuyinhloko ahanjiswa ngesithuthi sebhande siyiswe esomisini esijikelezayo ukuze somiswe ukuze kuncishiswe umswakama wama-granules aqediwe.Ngemuva kokumiswa, umswakama we-granules uzokwehla ukusuka ku-20% -30% kuya ku-2% -5%.

7. Ukupholisa ama-Granules: Ngemva kokoma, ama-granules azothunyelwa endaweni epholile ukuze iphole, exhunywe nesomisi ngesixhumi sebhande.Ukupholisa kungasusa uthuli, kuthuthukise ukusebenza kahle kokupholisa kanye nesilinganiso sokusetshenziswa kokushisa, futhi kuqhubeke kususe umswakama kumanyolo.

8. Ukuhlolwa kwesibili: Ngemva kokupholisa, wonke ama-granules angafaneleki ahlungwa ngomshini wokuhlola ojikelezayo futhi ahanjiswe ngesixhumi sebhande esiwa ku-mixer bese ehlanganiswa nezinye izinto zokusetshenziswa ukuze zicutshungulwe kabusha.Imikhiqizo eqediwe izothuthelwa emshinini wokuhlanganisa umanyolo ohlanganisiwe.

9. I-Coating: Isetshenziselwa ikakhulukazi ukugqoka ubuso be-quasi-granules ngefilimu yokuzivikela efanayo ukuze kunwetshwe ngokuphumelelayo isikhathi sokulondoloza nokwenza ama-granules abushelelezi.Ngemuva kokumboza, nansi inqubo yokugcina - ukupakishwa.

10. Uhlelo lokupakisha: Umshini wokupakisha wokulinganisa othomathikhi wamukelwa kule nqubo.Umshini wakhiwe umshini wokukala nokupakisha othomathikhi, uhlelo lokudlulisa, umshini wokuvala uphawu nokunye.I-Hopper nayo ingacushwa ngokuya ngezidingo zekhasimende.Ukupakishwa okulinganiselwe kwezinto eziningi ezifana nomanyolo we-organic kanye nomanyolo ohlanganisiwe sekusetshenziswe kabanzi ezimbonini nasezinkundleni ezahlukene.

Ubuchwepheshe kanye nezici zomugqa wokukhiqiza umanyolo ohlanganisiwe:

I-Rotary drum granulator isetshenziswa ikakhulukazi ekukhiqizeni ubuchwepheshe bomanyolo obuhlanganisiwe bokugxila okuphezulu, i-disc non-steam granulator ingasetshenziswa ekukhiqizeni ukuhlushwa okuphezulu, okuphakathi nendawo nokuphansi kobuchwepheshe bomanyolo obuhlanganisiwe, obuhlanganiswe nobuchwepheshe bokulwa namakhekhe, i-nitrogen ephezulu. ubuchwepheshe bokukhiqiza umanyolo obuhlanganisiwe nokunye.Ulayini wethu wokukhiqiza umanyolo oyinhlanganisela unalezi zimpawu ezilandelayo:

1. Ukusebenza okubanzi kwezinto ezingavuthiwe: umanyolo oyinhlanganisela ungakhiqizwa ngokuya ngendlela ehlukahlukene kanye nezilinganiso, futhi ulungele ukukhiqizwa komanyolo we-organic kanye ne-inorganic compound.

2. Izinga eliphezulu lokwakheka kwepellet kanye nezinga lokusinda lamabhaktheriya ebhayoloji: ubuchwepheshe obusha bungenza izinga lokwakheka kwe-pellet lifinyelele ku-90% ~ 95%, kanti izinga lokushisa eliphansi kanye nobuchwepheshe bomisa umoya ophezulu bungenza izinga lokusinda lamagciwane amancane. kufika ku-90%.Umkhiqizo oqediwe muhle ngokubukeka kanye nosayizi ofanayo, ama-90% awo angama-granules anosayizi we-2 ~ 4mm.

3. Ukugeleza kwenqubo eguquguqukayo: Ukugeleza kwenqubo yomugqa wokukhiqiza umanyolo ohlanganisiwe kungalungiswa ngokuya ngezinto zangempela zokusetshenziswa, ifomula kanye nesayithi, futhi ukugeleza kwenqubo okwenziwe ngezifiso nakho kungaklanywa ngokuya ngezidingo zangempela.

4. Isilinganiso esiqinile somsoco wemikhiqizo eqediwe: ngokusebenzisa ukulinganisa okuzenzakalelayo kwezithako, ukulinganisa okunembile kwazo zonke izinhlobo zezinto eziqinile, eziwuketshezi kanye nezinye izinto ezingavuthiwe, cishe kugcinwe ukuzinza nokusebenza kwazo zonke izakhi kuyo yonke inqubo.

CI-ompound Fertilizer Production LineIzinhlelo zokusebenza

1.Sulfur camera urea ukukhiqizwa inqubo.

2.Uhlobo oluhlukile lwenqubo kamanyolo we-organic kanye ne-inorganic.

3.Inqubo yokuhlanganisa umanyolo we-Acid.

4.Powdery industrial waste inqubo kamanyolo wezinto ezingaphili.

5.Inqubo yokukhiqiza i-urea yezinhlayiyana ezinkulu.

6.Inqubo yokukhiqiza umanyolo weSeedling Substrate.

Isikhathi sokuthumela: Sep-27-2020