Enye yezinzuzo ezinkulu zokusebenza no-Yi Zheng ulwazi lwethu oluphelele lwesistimu;asibona nje ochwepheshe engxenyeni eyodwa yenqubo, kodwa kunalokho, yonke ingxenye.Lokhu kusivumela ukuthi sinikeze amakhasimende ethu umbono ohlukile wokuthi ingxenye ngayinye yenqubo izosebenzisana kanjani iyonke.

Singahlinzeka ngezinhlelo eziphelele ze-granulation, noma izingcezu zemishini ngayinye yazo zombili izinhlelo ze-inorganic kanye ne-organic.

Ulayini wethu wokukhiqiza i-disc granulator ukhiqiza ikakhulukazi umanyolo oyinhlanganisela.Ngokuvamile, umanyolo ohlanganisiwe uqukethe okungenani izakhi ezimbili zezakhi ezintathu (i-nitrogen, i-phosphorus, ne-potassium).Ngokunezici zokuqukethwe okuphezulu kwezakhi, imiphumela engemihle embalwa, kanye nezakhiwo ezinhle zomzimba, umanyolo oyinhlanganisela udlala indima ebalulekile ekulinganiseni ukuvundiswa, ukuthuthukisa ukusebenza kahle kokufakwa kukamanyolo kanye nokukhuthaza isivuno esikhulu nesizinzile sezitshalo, umugqa wethu wokukhiqiza umanyolo ohlanganisiwe we-pan granulator wenzelwe ngokukhethekile. abakhiqizi bakamanyolo abanesidingo esikhulu sokukhipha.Lo mzila wokukhiqiza umanyolo ungakha umanyolo we-NPK, i-DAP futhi ugaye ezinye izinto zibe yizinhlayiya zikamanyolo ezihlanganisiwe.Ubuchwepheshe benqubo yalesi sitshalo sikamanyolo buthuthukile, buyasebenza futhi buyasebenza.Zonke izinto zokusebenza zikamanyolo zihlangene, zisebenza ngokuzenzakalelayo futhi kulula, okulula kakhulu ukukhiqizwa komanyolo ohlanganisiwe.

Inzuzo:

1.Yonke imishini kamanyolo isebenzisa izinto zokulwa nokugqwala nezingagugi.

2. Amandla ashintshekayo ngokwezidingo zekhasimende.

3. Akukho ukukhishwa kwemfucuza, ukonga amandla kanye nokunciphisa ukusetshenziswa, ukuvikela indawo.Ukusebenza okuzinzile, kulula ukuyinakekela.

4. Lo mugqa wokukhiqiza umanyolo awukwazi ukukhiqiza kuphela umanyolo ohlanganisiwe onokugxila okuphezulu, okuphakathi, nokuphansi, kodwa umanyolo we-organic, umanyolo we-inorganic, umanyolo we-bio kanye nomanyolo we-magnetizing njll. I-Disc granulator enezinga eliphezulu le-granulation.

5. Ngokwakheka okuhlangene, isethi ephelele yomugqa wokukhiqiza umanyolo ingokwesayensi futhi inengqondo, futhi ithuthukile kwezobuchwepheshe.

7. Ukuguquguquka okubanzi kwezinto zokusetshenziswa, ezifanele i-granulation kamanyolo ayinhlanganisela, imithi, amakhemikhali, isondlo nezinye izinto zokusetshenziswa.

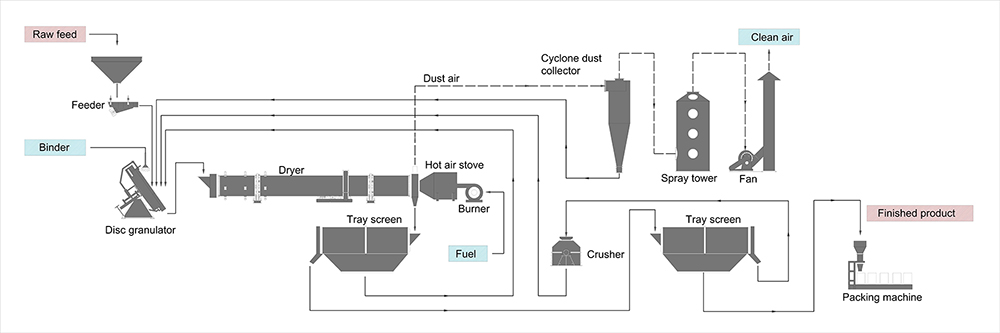

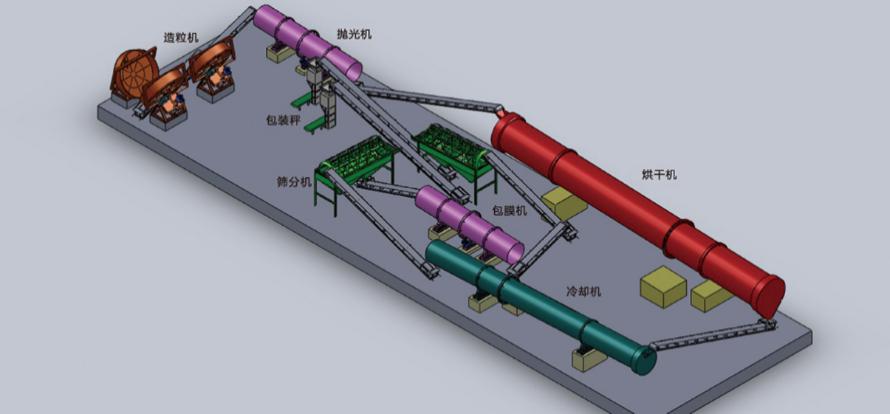

Wonke ulayini uhlanganisa i-Disc feeder (ukufaka izinto ethangini) → I-disc mixer (yokunyakazisa izinto ezingavuthiwe)→ i-crusher yeketango (yokuchoboza)→ I-Granulator yediski (yokuba yimbumbu)→ isomisi sesigubhu esijikelezayo(sokomiswa) → isipholile sesigubhu esijikelezayo (sokupholisa) → isikrini sesigubhu esijikelezayo (sokuhlola imikhiqizo eqediwe nengafaneleki)→ inqolobane yemikhiqizo eqediwe (yokugcina)→ iphakheji ezenzakalelayo (yokupakisha)→ isihambisi sebhande→igumbi lokulungisa uthuli→ isishintshi sokushisa

ISAZISO:Lo mugqa wokukhiqiza ungowereferensi yakho kuphela.

Inqubo yezobuchwepheshe ye-granulation yomugqa wokukhiqiza umanyolo oyinhlanganisela ingahlukaniswa ibe:

1.Inqubo Yokuhlanganisa Okubalulekile

Okokuqala, izinto zokusetshenziswa zinikezwa ngokuhambisana ngokuqinile nesilinganiso.Izinto zokusetshenziswa zihlanganisa i-urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, single superphosphate, coarse whiting), potassium chloride, potassium sulfate nokunye. ukusebenza kahle kukamanyolo.

2.Inqubo Yokugqugquzela Izinto

Izinto ezingavuthiwe zixubene ndawonye kumxube wediski onganyakazisa izinto ngokulinganayo.

3.Inqubo yokuchoboza

Umshini we-crusher we-chain uzochoboza into enkulu ibe yizicucu ezincane ezingahlangabezana nezidingo ze-granulation.Khona-ke i-conveyor yebhande izothumela izinto zokwakha ku-pan granulator ukuze i-granulate.

4.Inqubo yeGranulating

I-Disc fertilizer granulator isebenzisa isakhiwo se-arc disc angle.Izinga le-granulation lingafinyelela ngaphezu kwama-93%, elinezilinganiso ezingcono kakhulu ze-granulation phakathi kwazo zonke izicucu zikamanyolo.Ukusebenzisa i-counter-rotation eqhubekayo yesisetshenziswa kanye nedivaysi yokufafaza ukushayela izinto zokusetshenziswa ezigingqika kudiski.Ingakhiqiza ama-granules afanayo kanye nokubukeka okuhle.I-pan granulator ingumshini obalulekile kulayini wokukhiqiza umanyolo oyinhlanganisela.

5.Inqubo Yokomisa Nokupholisa

Ngemuva kwe-granulating, ama-granules adinga ukumiswa.Isihambisi sebhande sithutha ama-granules endaweni yokomisa imigqomo ejikelezayo.Umshini wokomisa ususa umswakama ezinhlayiyeni ukuze ukwandise ukushuba kwama-granules.Ngakho, ilungele ukugcinwa.Ngemuva kokumisa, izinga lokushisa lama-granules liphezulu, kulula ukuhlanganisa.Ngakho-ke sidinga ukupholisa ama-granules ngomshini wokupholisa isigubhu esijikelezayo.Ngemva kokuba selehlile, ama-granules kamanyolo kulula ukupakisha, ukulondolozwa kanye nokuthutha.

6.Inqubo Yokuhlukaniswa Kwengxenye

Umanyolo kufanele uhlolwe ngomshini wokuhlola imigqomo oyi-rotary ngemva kokuba upholile.Imikhiqizo efanelekile izothunyelwa endaweni yokugcina impahla eqediwe nge-conveyor yebhande noma ingapakishwa ngokuqondile.Ama-granules angafaneleki azokwenziwa kabusha.

7.Inqubo Yokupakisha Umkhiqizo

Ukupakisha kuyinqubo yokugcina kulayini wokukhiqiza umanyolo oyinhlanganisela.Iphasela likamanyolo elizenzakalelayo eliphelele lisetshenziselwa ukupakisha imikhiqizo eqediwe.Ngokuzenzakalela okuphezulu nokusebenza kahle okuphezulu, akuzuzi nje kuphela ukukala okunembile, kodwa kufeza inqubo yokugcina yesu kahle kakhulu.Amakhasimende angakwazi ukulawula isivinini sokuphakela bese usetha ipharamitha yesivinini ngokwezidingo zangempela.

Isikhathi sokuthumela: Sep-27-2020