Enye yezinzuzo ezinkulu zokusebenza no-Yi Zheng ulwazi lwethu oluphelele lwesistimu;asibona nje ochwepheshe engxenyeni eyodwa yenqubo, kodwa kunalokho, yonke ingxenye.Lokhu kusivumela ukuthi sinikeze amakhasimende ethu umbono ohlukile wokuthi ingxenye ngayinye yenqubo izosebenzisana kanjani iyonke.

Singahlinzeka ngezinhlelo eziphelele ze-granulation, noma izingcezu zemishini ngayinye yazo zombili izinhlelo ze-inorganic kanye ne-organic.

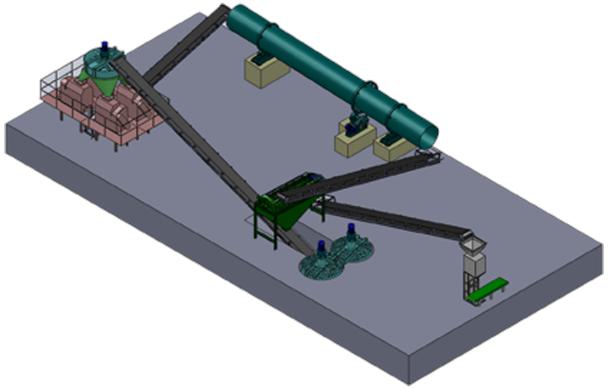

Singahlinzeka ngomklamo wenqubo kanye nokuhlinzekwa kwawo wonke ulayini wokukhiqiza umanyolo we-extrusion ongasomisi.Izinto zokusebenza zazihlanganisa i-Hopper & Feeder, i-roller (Extrusion) Granulator, isikrini esijikelezayo, i-Bucket Elevator, i-Belt Conveyor, umshini wokupakisha kanye ne-Scrubber.

Lokhu I-Roller (Extrusion) ulayini wokukhiqiza i-granulator ingakhiqiza umanyolo ohlanganiswe phezulu, ophakathi nendawo futhi ophansi wezitshalo ezihlukahlukene.Nge-granulator ekabili ukukhiqiza ama-granules, ulayini wokukhiqiza awudingi inqubo yokomisa, nokuba nemali encane kanye nokusetshenziswa kwamandla okuphansi.Amarola okucindezela we-granulator angaklanywa ukwenza izimo ezihlukene nosayizi bezinto.Ulayini uhlanganisa umshini wokuhlanganisa othomathikhi, okuthutha amabhande, izixube zamapani, i-pan feeder, ama-extrusion granulator, umshini wokuhlola ojikelezayo, indawo yokugcina impahla eqediwe, kanye nomshini wokupakisha ozenzakalelayo.Sikulungele ukunikeza imishini kamanyolo enokwethenjelwa kakhulu kanye nezixazululo ezifanele kakhulu kumakhasimende ethu ahlonishwayo.

Izinzuzo:

1. Yamukela ukucindezela komshini ukuze wenze ama-granules, asikho isidingo sokushisa noma ukuthulisa izinto zokusetshenziswa

2. Ifanele izinto ezizwela ukushisa, njenge-ammonium bicarbonate

3. Asikho isidingo sokumisa inqubo, ukutshalwa kwezimali okuphansi, ukusetshenziswa kwamandla okuphansi.

4.Akukho manzi angcolile noma ukukhishwa kwegesi engcolile, akukho ukungcoliswa kwemvelo.

5. Ukusabalalisa usayizi wezinhlayiyana ezifanayo, akukho ukuhlanganisa.

6. Isakhiwo esihlangene, ubuchwepheshe obuphambili, ukusebenza okuzinzile, ukugcinwa okulula.

7. Ukusebenza okulula, ukuqaphela ukulawula okuzenzakalelayo, ukwandisa ukusebenza kahle kokukhiqiza.

8. Uhla olubanzi lwesicelo sezinto zokusetshenziswa, azikho izidingo ezikhethekile zezakhiwo

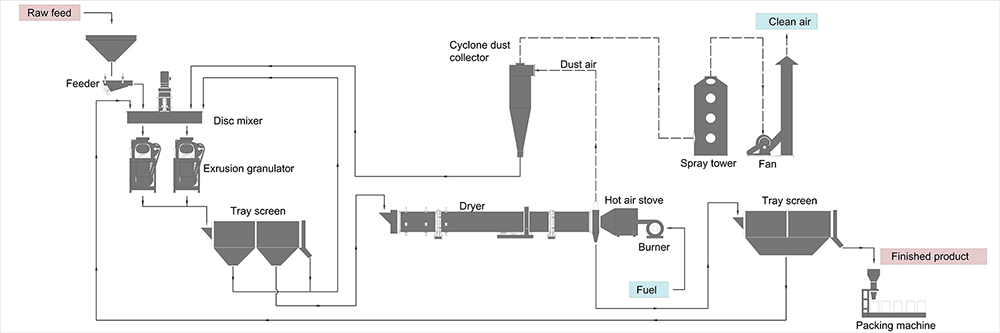

Pi-rocess

1. Automatic Batching Machine

Okokuqala, izinto ezahlukahlukene zihlukaniswa ngokwefomula ngomshini wokuhlanganisa imigqomo emi-5, ongagcwalisa izinto zokuhlanganisa ngokuzenzakalelayo ngokunemba okuphezulu nokusebenza kahle okuphezulu, ngaleyo ndlela ikhwalithi yomanyolo iyaqinisekiswa.Ngemuva kokuhlanganisa, izinto ezisetshenziswayo zidluliselwa kumxube we-pan.

2. I-Disc Mixer

Samukela amasethi amabili ezixube zamadiski kulo mugqa wokukhiqiza umanyolo.I-cycloidal reducer ishayela i-shaft eyinhloko ukuze ijikeleze, bese yona ishayela izingalo ezinyakazayo.Ngokunyakaziswa kwezingalo ezinyakazayo namafosholo amancane kuzo, izinto zokusetshenziswa zixubene ngokugcwele.Ngemuva kokuxuba, izinto ezisetshenziswayo zikhishwa ekuphumeni ngezansi.Uhlangothi lwangaphakathi lwediski luthatha ipuleti le-polypropylene noma insimbi engagqwali, okwenza izinto ezinganamatheli kalula, kanye nokumelana nokuhuzuka.

3. I-Double Roller Fertilizer Granulator

Nge-conveyor yebhande, izinto zokusetshenziswa ezixutshwe kahle zihanjiswa kusiphakeli sepani, esiphakela izinto ngokulinganayo kuma-granulator amane okukhipha ngaphansi kwesiphakeli ngokusebenzisa i-hopper.Nge-counter-rotation high pressure rollers, izinto ezisetshenziswayo zikhishwa zibe izingcezu.Izingcezu zigeleza phansi ekamelweni lokuchoboza ngaphansi kwe-roller yokunyathelisa, lapho zichotshozwa khona ama-roller ahlabayo futhi zihlolwe ukuze zithole i-granular edingekayo.Amarola omshini athatha uhlobo olusha lwensimbi olumelana nokugqwala, ukuguga kanye nomthelela.

4. Umshini Wokuhlola I-Rotary

Ngebhande elihambisa ama-granules, ama-granules asuka ku-extrusion granulator athunyelwa emshinini wokuhlola ojikelezayo, lapho ama-granules angafaneleki edlula endaweni yokuvula isikrini futhi aphume nge-outlet engezansi, abese ephindiselwa emuva kusiphakeli se-pan, kuyilapho ama-granules afanelekayo ephumela ngaphandle. i-outlet ekugcineni engezansi yomshini futhi idluliselwe endaweni yokugcina impahla ephelile.

5. Umshini Wokupakisha Ozenzakalelayo

Ngokusebenzisa indawo yokugcina impahla eqediwe, ama-granules afanelekayo akalwa futhi apakishwe umshini wokupakisha othomathikhi.Iyunithi inomshini wokukala nokupakisha ozenzakalelayo, idivayisi yokudlulisa, idivayisi yokuvala kanye nesiphakeli.Inezici zokunemba okuphezulu kwesisindo, ukusebenza okuzinzile, ukusetshenziswa kwamandla okuphansi, nokuhlala okuncane komhlaba.

Isikhathi sokuthumela: Sep-27-2020